Delrin® outperforms acetal copolymer

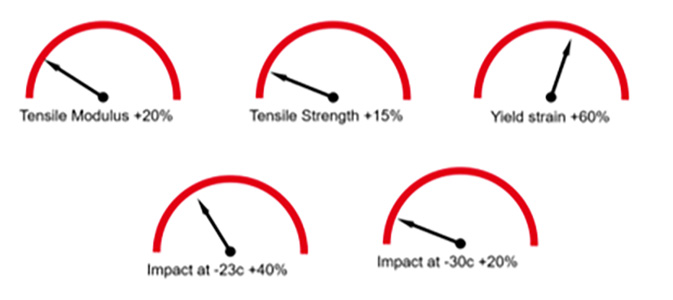

Delrin® acetal homopolymer outperforms acetal copolymer in most mechanical tests that are key to a long lifetime gear.

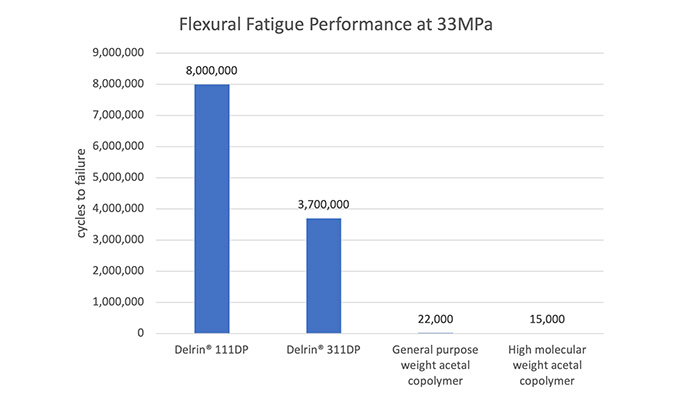

Fatigue

When comparing the performance of an identical gear in Delrin® to acetal copolymer, the lifetime improvement is significant. This is because the acetal copolymer is a less stiff material, meaning it flexes more and so generates greater internal heat. The result is premature failure with the acetal copolymer gear, whereas the Delrin® gears keep running.

Based on internal DuPont testing per ASTM D671 at 30Hz and 33MPa (4750 psi) at 23°C initial temp.

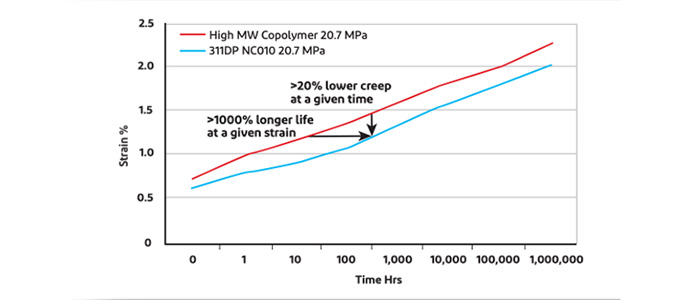

Creep

Molded plastic gears are best used in applications without static loads.

If static loads cannot be avoided, the creep performance of the material needs to be considered and gears designed to operate properly after the teeth have deflected due to creep.

Delrin® offers superior creep resistance versus most unreinforced engineering polymer types including acetal copolymers. Design engineers can be confident in its performance without the need for glass-reinforced alternatives, which can compromise impact performance and dimensional stability.

Based on internal accelerated flexural creep testing.

All of these advantages combine so Delrin® performs in gears when other plastic materials cannot meet the load requirements.

More information can also be found in the white paper, Delrin® Acetal Homopolymer Outperforms Acetal Copolymer and Reduces Cost Per Part.