Delrin® POM thermoplastic resins may be processed on conventional injection molding machines using standard industry practices.

Molding Tips to Optimize Production of Components Made with Delrin® Acetal Homopolymer

Delrin® acetal resins are molded throughout the world in a wide variety of types and designs of injection equipment. The guidelines below will help deliver the excellent mechanical performance achievable with Delrin resins.

DuPont™ Engineering Polymers

General Design Principles – Module I

General Design Principles for Delrin® Engineering Polymers

This section is to be used in conjunction with the product data for specific Delrin® Engineering thermoplastic resins—Delrin® acetal resins. Designers new to plastics design must consider carefully the aspects of plastic properties which differ from those of metals: specifically, the effect of environment on properties, and the effect of long term loading.

Delrin® Acetal Homopolymer White Paper

emission (VDA 275) Creep performance Molding performance Delrin® 100 Delrin® 100P Delrin® 100CPE 100% 80% 60% 20% 40% 0% Tensile modulus Delrin ® CPE – A New Platform of Emission- minimized POM Homopolymers with Optimized Processing Efficiency

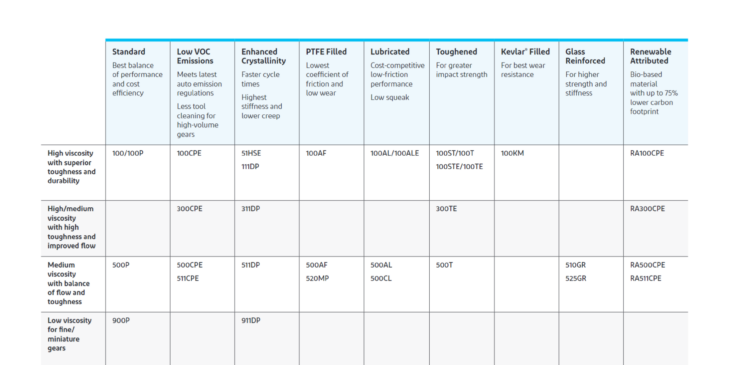

Delrin® Grade Selector for Gears

Delrin® Grade Selector for Gears

Delrin® Design Guide

Delrin®, the world’s first acetal resin, is a highly versatile engineering plastic with metal-like properties.