Want your products to be more reliable, produce less noise and have a longer lifetime? Delrin ® has inherent low friction and good wear properties that can make it happen.

Delrin® Gears for E-bikes Help Reduce Greenhouse Gas Emissions

Delrin® Gears for E-bikes Help Reduce Greenhouse Gas Emissions Challenge Greenhouse gases are directly linked to global warming and in Europe, transportation is responsible for an estimated 30% of the total. Working toward a goal of becoming carbon neutral in…

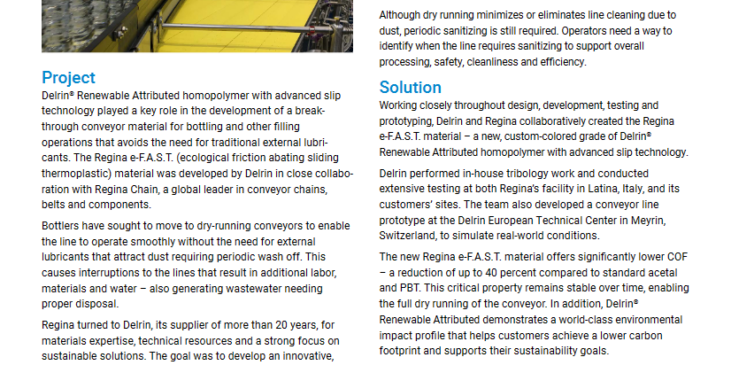

Delrin® Drives Productivity and Sustainability for High Speed Filling Lines

Delrin® Renewable Attributed homopolymer with advanced slip technology played a key role in the development of a break- through conveyor material for bottling and other filling operations that avoids the need for traditional external lubri- cants. The Regina e-F.A.S.T. (ecological friction abating sliding thermoplastic) material was developed by Delrin in close collabo- ration with Regina Chain, a global leader in conveyor chains, belts and components.

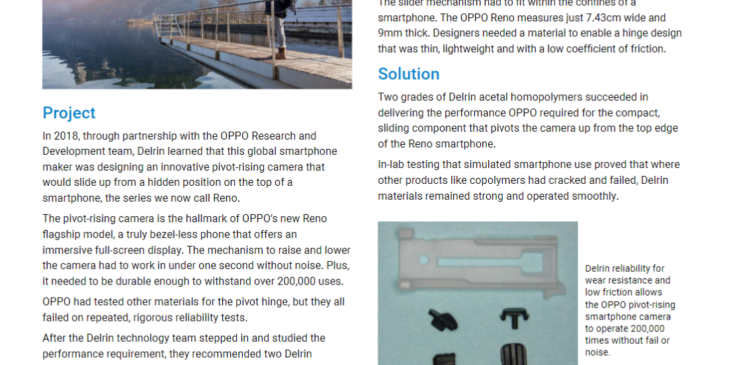

Low-Friction, Low-Noise Delrin® Unleashes the Power in OPPO’s Smartphone with Pivot-rising Camera

In 2018, through partnership with the OPPO Research and Development team, Delrin learned that this global smartphone maker was designing an innovative pivot-rising camera that would slide up from a hidden position on the top of a smartphone, the series we now call Reno.

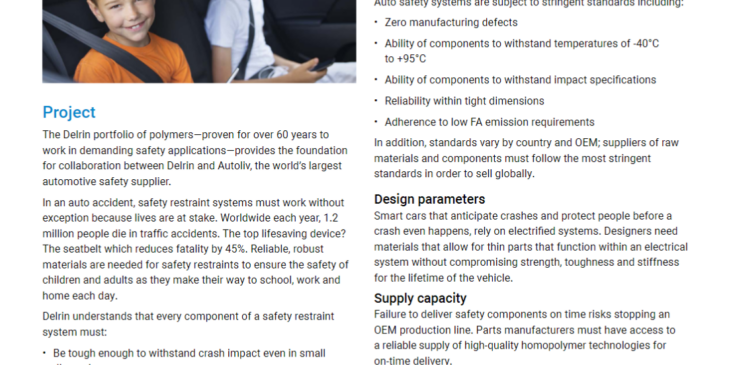

Delrin® Components Meet Strict Standards for Life-Saving Automotive Safety Restraint Systems

The Delrin portfolio of polymers—proven for over 60 years to work in demanding safety applications—provides the foundation for collaboration between Delrin and Autoliv, the world’s largest automotive safety supplier.

Creep and Stress Relaxation

Welcome to the Delrin® Solution Series, your guide to successful part design with Delrin acetal homopolymer resin.

LIP Moves Production into High Gear with Delrin® 100CPE Acetal Homopolymer

Delrin® 100CPE resin is the successor to the well-established Delrin® 100 series, known for high strength, precision and fatigue resistance.

Acetal Homopolymer vs Copolymer | Delrin®

A major customer used Delrin® acetal homopolymer over acetal copolymer to redesign the next generation of their part. The result: thinner, lighter part design at same part performance that allowed the company to shorten production cycle time and to gain significant cost savings in part production cost.

High Mechanical Strength | Delrin® Case Study

Ford Seat Design Relies on Delrin® Toughness and Load Stiffness At Ford Motor Company, innovation and a commitment to safety are core values that helped drive the development of an award-winning seat system that provides greater comfort and safety, including…